Capabilities

Industrial Design Services

Our industrial design services drive innovation by using a human-centric design focus leading to products and instruments that are physically and digitally intuitive, easy to use, and highly functional.

Good industrial design considers all aspects of user experience, mechanical functionality, and manufacturing concerns, balanced with the client’s key objectives of features, cost targets, and timeline.

At Invetech, industrial design starts from the very beginning of a project by understanding the user and maintaining the original design intent all the way through to manufacturing of the product.

Having the full range of industrial and product design services in-house allows all members of the project team complete access and visibility to the entire development path. This is key to Invetech driving the optimal solution to the market in the fastest time possible with the least re-iterative efforts for our clients.

Our approach

Industrial design starts by merging optimal user experience with client business objectives.

At Invetech, we provide industrial design services in the following step-by-step process to guarantee the best product outcome:

1 | ResearchOur industrial design process starts with research to understand the client’s key objectives, client’s voice of customer (VOC), the competitive product landscape and market trends. |

2 | Brainstorming and early concept generationThen we start our brainstorming process to find innovations and start early concept development. |

3 | User interface studiesWe will work with our Experience Design (XD) group to immerse ourselves in the User’s experience. Then start concept sketching and building rough 3D mockup to test with Users. This iterative concept development will go through many cycles. |

4 |

|

5 | Concept refinementFurther refinement includes CMF study to evaluate colors, materials and finishes where appropriate for the market as well as maintaining cost targets. |

6 |

|

7 | 3D CAD modelsFrom there we’ll start to build 3D CAD models to ensure the mechanical components are well integrated. In addition, we will create photoreal CAD renderings to further evaluate CMF options. |

8 | Appearance modelsIf needed by the client for tradeshow or investor purposes, we will create appearance models that very closely resemble the actual product design. |

9 | Maintain original design intent through productionFinally, we maintain the client’s agreed upon original design intent through the many months of technical development that occurs prior to final manufacturing production. |

Putting the user at the center of product design

Focusing on the user is key to creating an intuitive, easy-to-use instrument that conforms to physical demands. This idea drives our industrial design services as an integral part of our product development process.

In the video clip below, Kfir Oved, CTO of MedMed, discusses one way to better design products around the user during a panel discussion hosted by Invetech. In their case, this meant building a medical diagnostic device to serve very different end users, in very different settings – starting from the central lab, going through the emergency department, the outpatient setting and even patient home care.

Our design culture

Invetech is serious about industrial design and passionate about creating products that are customer-centric, intuitive and simple to interact with both physically and digitally.

Our industrial design services include:

- Research and problem definition

- Innovation

- Concept development, visualization and mock-up creation (2D and 3D)

- Ergonomic and usability development

- Product image renderings, model and prototype making

- Manufacturing and assembly knowledge

Why Invetech leads industrial design

Many industrial design firms create attractive product designs based on a customer-centric approach. And many engineering firms create functional instruments that perform well. But few firms combine intuitive designs with high functionality and reliability. Invetech provides both.

Our designers work collaboratively with team members across the full product development spectrum, from user experience design to mechanical and electrical engineering, medical scientists, software developers and contract manufacturing to creatively problem solve and arrive at innovative solutions.

By seeking constant feedback from all project team members throughout the product development process, we are able to avoid the snarl of conflicting compliance demands, communication misfires, and the consequent increase in development time that could happen when design and development are more siloed.

Invetech’s key advantage is this seamless merging of distinct teams, and our process of continual collaboration throughout the project, delivering intuitive, elegant and functional design. This dynamic communication between teams ensures all perspectives are represented, improving efficiency, ensuring compliance, and guaranteeing customer satisfaction.

Let’s bring your idea to life

Our industrial design team drives innovation by using a human-centric design focus leading to products and instruments that are physically and digitally intuitive, easy to use, and highly functional.

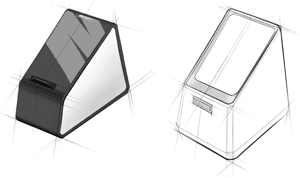

Instrument concept sketching

Instrument concept sketching 3D mock-ups

3D mock-ups